Best alternative to I2C sensors for embedded systems

This article is aimed at small development teams working on large-scale products, where engineering time is highly valued and critical to the go-to-market strategy.

Why evaluate solutions other than I2C?

For many engineers, integrating I2C sensors into embedded systems feels like the natural choice. The I2C industry standard offers direct access to environmental data, but it also brings a set of challenges that can slow down development and complicate product design. Designing the PCB layout, handling signal integrity issues, writing low-level firmware, implementing environmental compensation and debugging communication protocols are all time-consuming tasks. Scaling the system introduces even more complexity, requiring firmware updates and additional validation with each new sensor. And if ever the sensor has to undergo recalibration activities due to normative requirements, the end-user has to call on the manufacturer for support to get the job done.

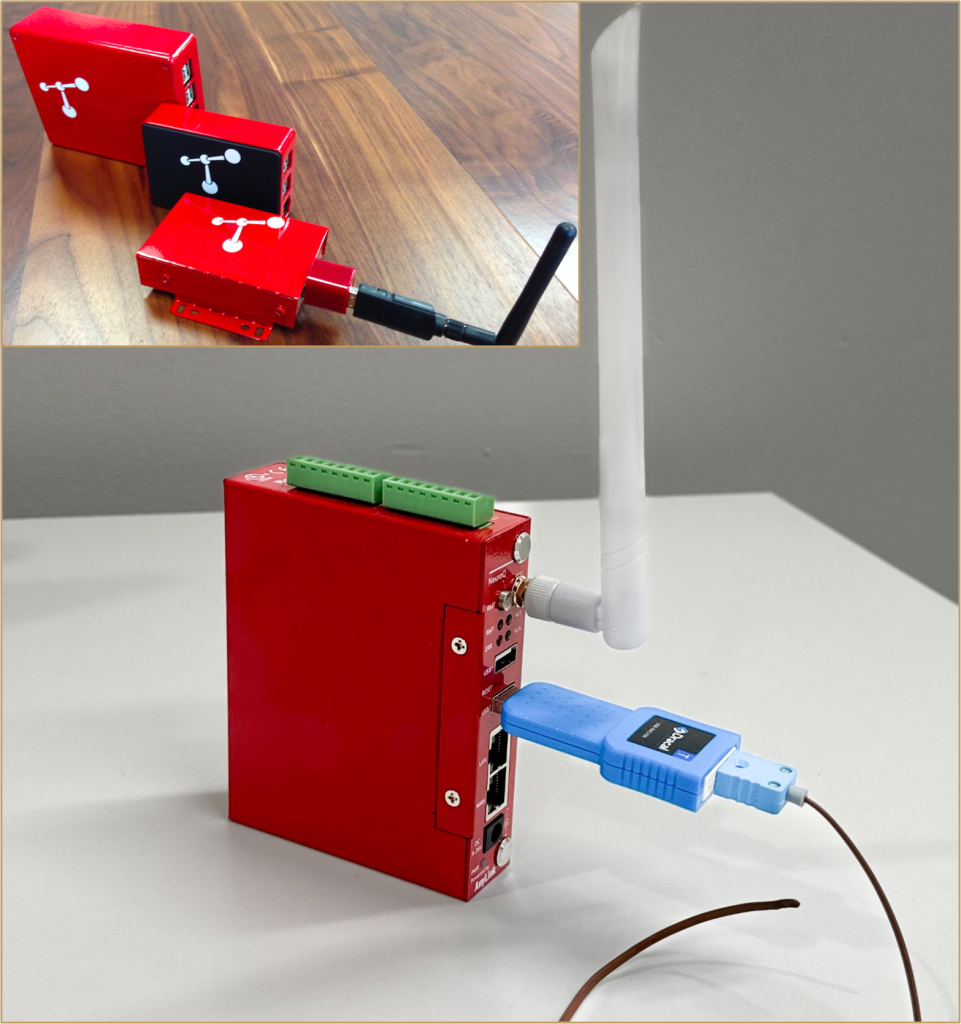

Dracal USB sensors offer a different approach. Instead of spending weeks integrating an I2C sensor, debugging firmware, and fine-tuning your board design, what if you could simply connect a high-precision sensor to your system and start collecting data immediately. No custom drivers, no extra components, just reliable measurements accessible through standard USB port and the COM (serial) protocol that any developer can interface with.

Example of Dracal sensors for easy embedded integration

Rethinking sensor integration and interfacing

When considering alternatives to I2C sensors, engineers typically look at SPI sensors for higher speed, or wireless options like Bluetooth and LoRa for remote applications. But both still require additional hardware, firmware, and debugging effort. USB, often overlooked in embedded applications, eliminates these headaches.

With Dracal USB sensors communicating via COM (serial) protocol, there’s no need to write low-level communication code or worry about hardware design constraints. They are cross-platform, factory-calibrated, and work instantly on Linux, Windows, and macOS. Instead of spending weeks designing around I2C limitations, you can focus on application-level development and system functionality. Additionally, Dracal sensors allow for easy end-user recalibration, ensuring long-term measurement accuracy without needing to return the device to the manufacturer.

Faster development, scalable design

Developing with I2C sensors requires careful PCB design, firmware development, and extensive validation at every stage. Engineers must account for noise issues, signal integrity, and address conflicts, all of which add complexity and time to the process. Scaling up by adding new sensors often means modifying firmware, adjusting board layouts, and redoing compliance testing, which slows down deployment.

Dracal USB sensors eliminate these bottlenecks. Since they operate as standard USB or virtual COM devices, they bypass the need for custom PCB integration and low-level communication handling. Engineers can integrate them immediately without writing or maintaining I2C drivers. Scaling the system is effortless—simply connect additional sensors via USB without modifying firmware or redesigning hardware. Dracal sensors also support end-user recalibration, ensuring long-term accuracy without requiring replacements or factory servicing. This significantly reduces downtime and maintenance costs, making them a robust, future-proof solution for embedded systems.

Counteract the lack of focus that can lead to the undoing of your project

Although I2C technology is designed for integrating sensors into embedded systems, precision sensor integration doesn’t end with obtaining data. Indeed, the mere act of soldering a component onto a PCB and positioning it among other components creates a new ecosystem in which the sensor must be guaranteed to preserve its characteristics. And it is the integrator who is responsible for ensuring, through automated testing, environmental compensation and other analysis, the sensor’s final performance.

So, if the core of your project is not the integration of low-level sensors into your product, but rather the ability to benefit from precision data, embarking on the design stages of a measuring instrument could be lethal to the project’s survival. Here, focus will separate the winners (you!) from the others.

The engineer’s choice

I2C is powerful, but it comes at a cost—time, complexity, and maintainability. If your project demands fast, reliable environmental measurements without the overhead of custom firmware and hardware tuning, Dracal USB sensors provide a streamlined alternative. You don’t need to reinvent the wheel every time you add a new sensor. Just plug it in and get to work, with the added benefit of on-site recalibration for sustained accuracy.

PRODUCTS YOU CAN TRUST

Approved by engineers, scientists and researchers around the world.

Thousands of companies trust our products worldwide:

Not sure if your project will benefit from Dracal’s solution?

Contact us, tell us about your project, and we’ll quickly determine if there’s a fit.

"*" indicates required fields

Always offered at no extra charge with our products!

EASY TO USE IN YOUR OWN SYSTEM

- Ready-to-use, accurate and robust real-time data flow

- Choose the interface that works best for you (CLI, virtual COM, REST API)

- Code samples available in 10+ programming languages (Python, C/C++, C#, Java, Node, .Net, etc.)

- Operates under Windows, Mac OS X and Linux

- Usable with LabView (CLI guide, Virtual COM guide)

- All tools packaged within one simple, free of charge, DracalView download

FREE DATA VISUALIZATION, LOGGING AND CALIBRATION SOFTWARE

- Get up-and-running in less than 3 minutes

- Operates under Windows, Mac OS X and Linux

- Real-time on-screen graphing and logging

- Log interval down to 0.5 second and configurable units (°C, °F, K…)

- Simultaneous use of unlimited Dracal sensors supported

- Simple user-calibration (products with the -CAL option)

- Connectivity with SensGate Wi-Fi/Ethernet gateway