Acquire data for audio product development in less than 5 minutes

Who is this use case for?

Engineers, researchers, and technicians in the audio and acoustics industry who require efficient and user-friendly solutions for data collection, environmental monitoring, and automation across various setups, including R&D and manufacturing.

What is this about?

Continuously monitor the environmental conditions affecting audio equipment development in a context where ease of use, rapid deployment, and integration capabilities are discriminant criteria.

Customer Story

Feedback from a the Principal Acoustic Engineer of a manufacturer of high-quality audio and acoustic equipment manufacturer

″I’ve used your products in the past, and bought a few PTH450 here to show the team how easy it is to set up and use vs other options like Omega, NI, etc. I did a demo at a meeting where someone was able to collect data in < 5 mins using some short instructions on install and commands.

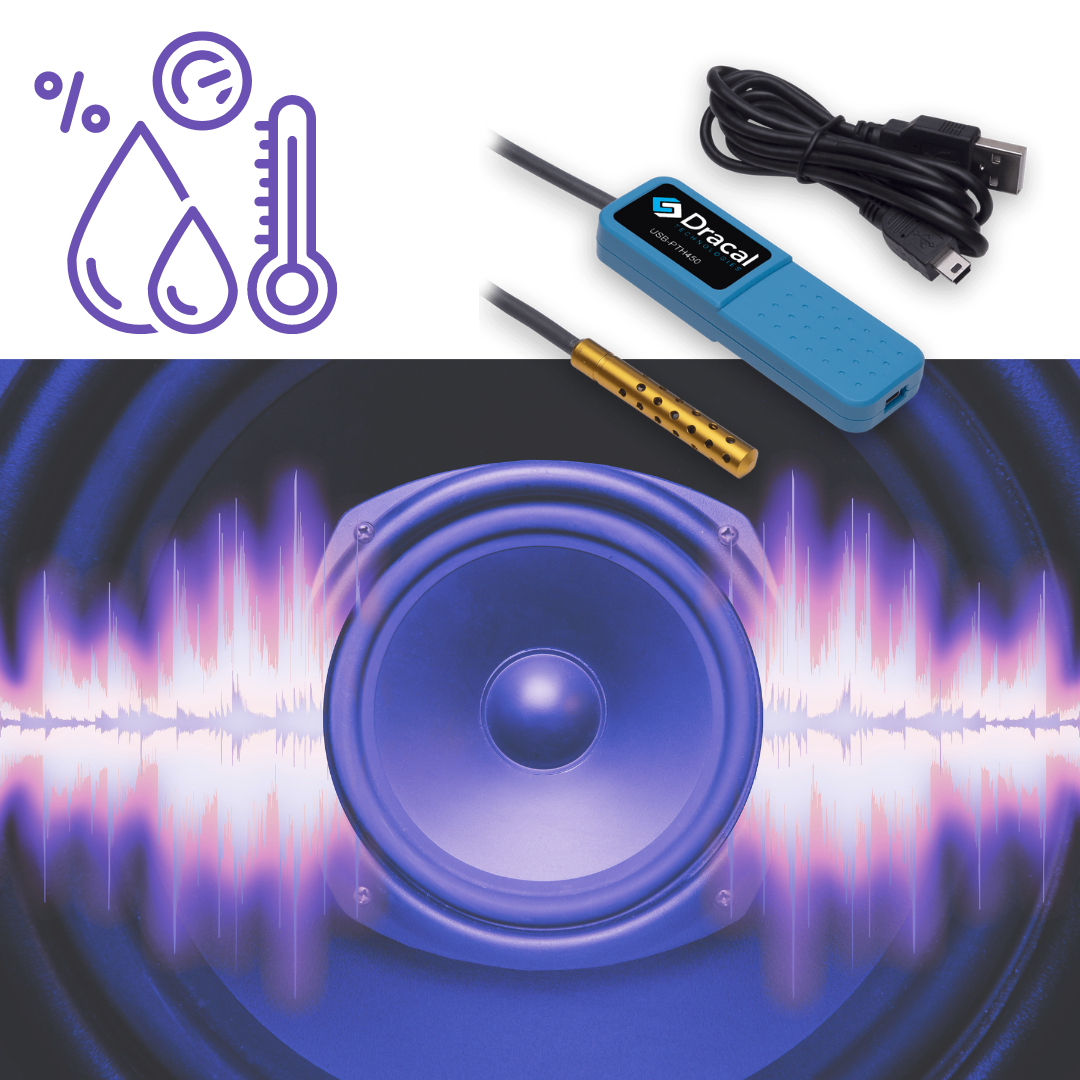

All 3 parameters (measured by the PTH450) can affect acoustic frequency response in subtle, but measurable, ways:

• Temperature can have a direct effect on resistance, which is most often seen in variation in loudspeaker sensitivity due to changes in voice coil resistance. Speed of sound also changes with temperature (and humidity), so it can be helpful to track in certain test setups where delay and phase are important.

• Humidity can change the moving mass of speaker components like paper cones and fabric suspensions, as well as be tied to defects of acoustic components like speakers and mics (and I’m sure electronics).

• Pressure can change the effective stiffness of air volumes. I haven’t seen it vary at a single location enough to have a large effect, but it can be important across locations and easy to forget about if you’re not taking data.

I’ve liked the ease of use of your products, where you’ve obviously put effort into it, and its nice working with smaller companies who are more responsive to non-giant customers. Your tools for automation (via CMD!) makes the products easy to use across setups (R&D, manufacturing) without worries about cost or complex installs for things like C, python, VB, matlab, etc.″

Challenge

The development team quickly needs to access and deploy precision environmental data in various projects to evaluate their new equipment under various operating conditions. They need a solution that is easier to set up and use than more "standard" solutions, which usually require extensive set-up and complex installations.

Solution

Dracal PTH450 all-in-one sensors are hard to beat in terms of simplicity and efficiency. Following brief instructions for installation and execution of simple commands, a new user can create a data integration task from the ground up in less than 5 minutes live in front of colleagues. The PTH450 is adopted as the simplest-to-integrate, accurate all-in-one sensor for air condition monitoring.

Prerequisites and limitations

To implement this solution, the following prerequisites and limitations are considered:

- Basic instructions for installation and command execution.

- Availability of a computer for data logging and command execution.

- Initial purchase of Dracal products, which offers significant ease of use and efficiency benefits.

Implementation

- Purchase the PTH450 all-in-one temperature, relative humidity, and atmospheric pressure USB sensor.

- Install Dracal Software

- Quickly visualize your measurements with DracalView

- Take knowledge of the tutorial on getting started with command-line tools

- Consult the ready-to-use code examples available in the resources for integrators to integrate the Dracal data flow into your current system quickly

State after implementation

In just a few minutes, the team set up a complete data acquisition system that is simple, reliable and inexpensive, enabling them to record and consult critical data while saving time and money. There are significant improvements in the ease and speed of data collection without concerns about cost or complex installations for languages like C, Python, VB, and Matlab, thanks to Dracal’s automation tools (via CMD). The products are appreciated for their user-friendly design and responsiveness without sacrificing the reliability and precision required for the task.